| Oil cup size (diameter) | 90mm | Rubber head drop cylinder diameter | 63mm |

| Plate size | 100*250mm/150*300mm | Glue head pressure | 1870N |

| speed | 6 seconds/cycle | Current supply | 110/220V |

| Maximum printing center travel | 125mm | Accuracy +/- | 0.025mm |

| Machine travel | 175mm | weight | 250 kg |

| Servo push left and right stroke | 0-700mm | Size (L * W * H) | 1121*1126*1619mm |

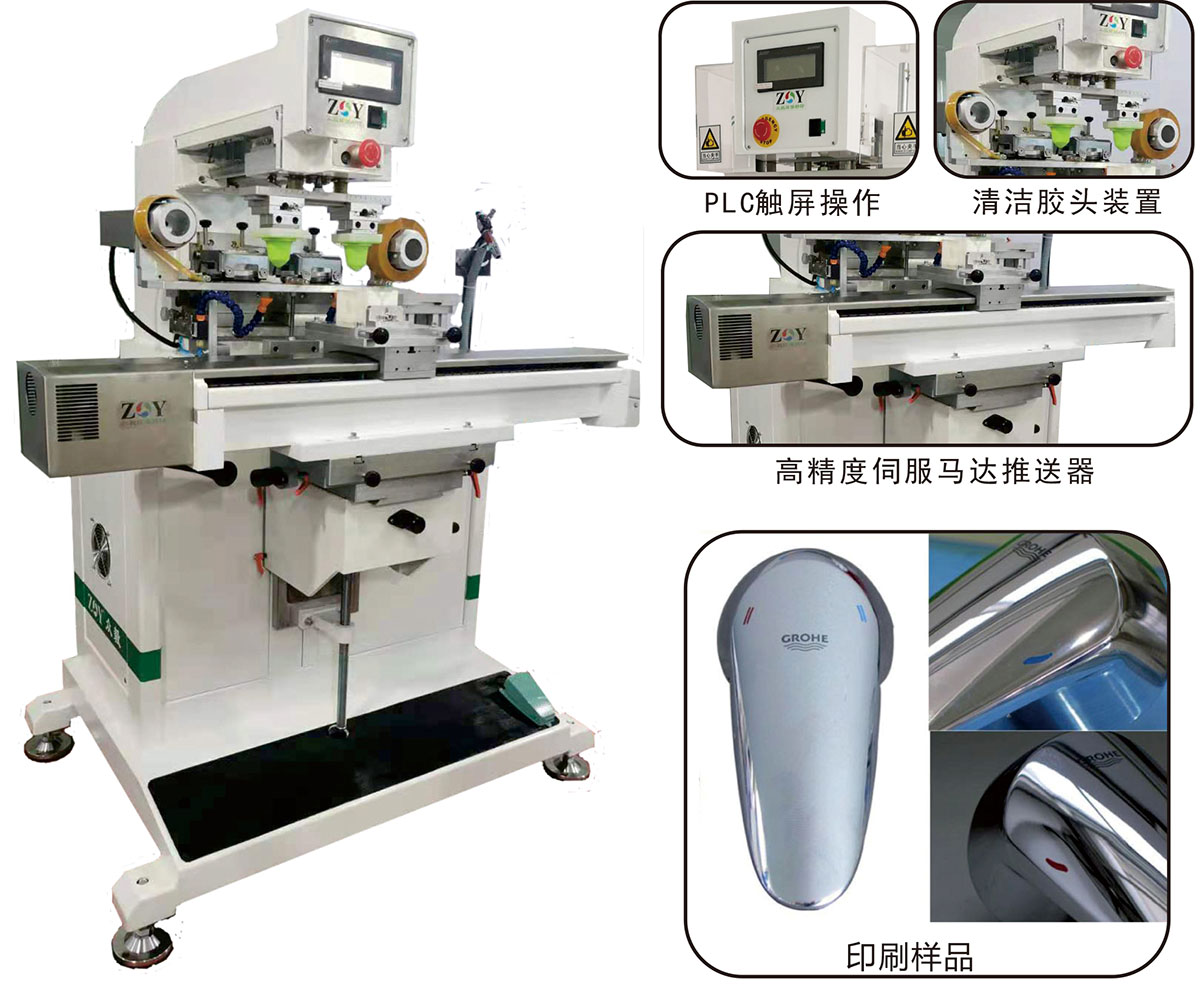

High-grade alloy cast aluminum, the most competitive market

Printing position does not need to be adjusted

CNC printing depth and delay system

Optional CNC hot air system

PLC man-machine control interface

Sealed oil cup

High precision servo motor drives left and right push

Automatic intelligent electric cleaning system

Precision bearings and guide rails

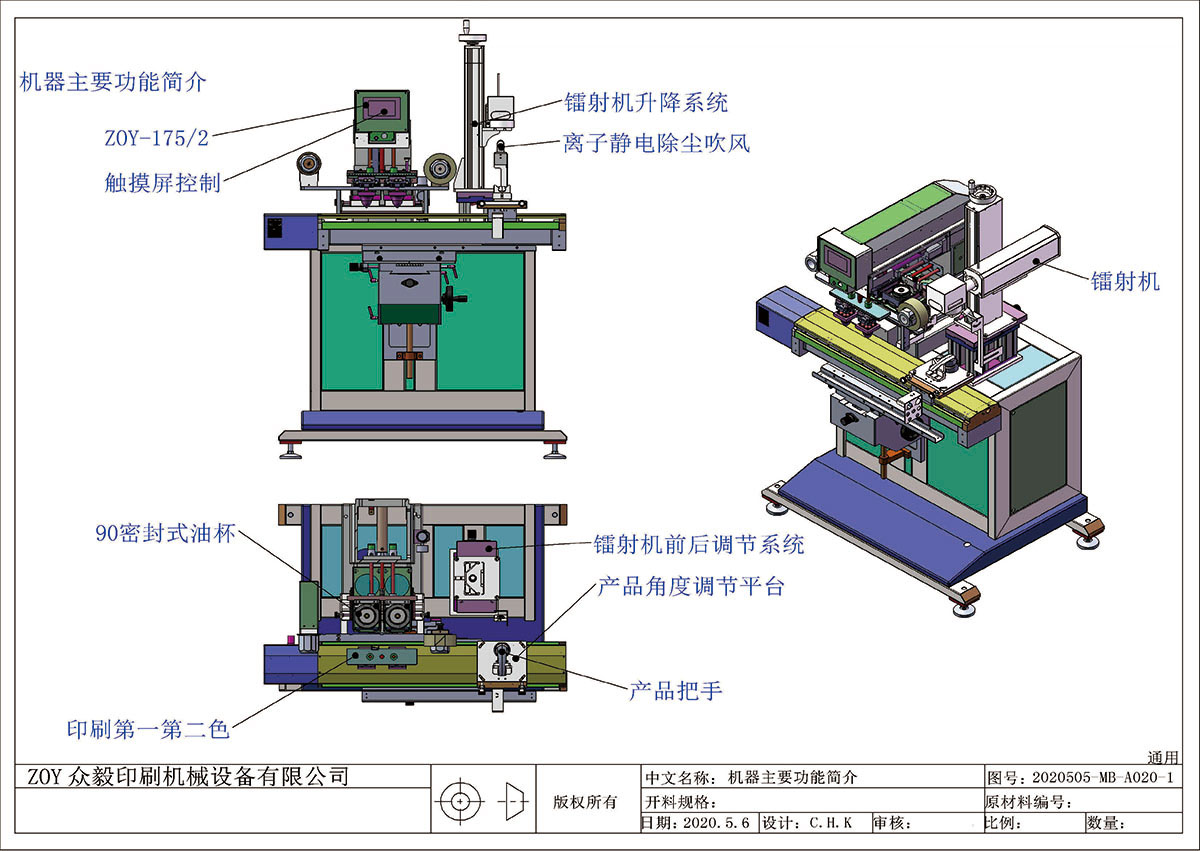

1.Z0Y-175/2-DRE faucet two-color laser pad printing system

-Servo motor drives the printing platform to push left and right - precision cylinder drives the rubber head to push back and forth

-PLC touch control panel (more flexible and easy to operate human-machine interface)

- Computer program to control the data can ensure the printing color difference, printing quality is more stable - two-color cold air can be manually adjusted to control the printing quality

2.diameter 90mm oil cup 4PC

3.zero adjustment oil cup printing platform (with cross positioning printing steel sheet, glue head, can be replaced printing plate and glue head zero adjustment, to achieve rapid conversion)

4.100*200/100*250mm printing version

5.1po forming alignment fixture

6.electric intelligent cleaning glue head device - to ensure printing quality, reduce waste

7.HIWIN bead screw, THK guide rail, NSK precision bearing

8.MITSUBISHI programmable control system can store 20 sets of memory data

9.PANASONIC/OMRON/NEC electronic parts

10.SANYO servo motor driver

11.SMC or FEST0 pneumatic components

12.SCHNEIDER, CHNT, ABB brand leakage circuit breaker

13.multi-color printing blower components

14.advanced alloy cast aluminum body, industrial heavy chassis (head lengthening, frame widening)

Servo stroke: 0-700mm

Oil cup size: 90mm diameter

Steel plate/steel sheet size: 100*200/100*250mm

Maximum glue head pressure: 3740N

Power/Frequency: 220V/50HZ

Air Pressure: 6Bar(approx.)

1、the products are placed in the positioning center in order

2、servo drive marking

3、servo control printing pattern

4、printing is completed, people hand material

Statement: The production rate of the machine is affected by the following conditions: printing requirements, ink change conditions, feed/feed control, rubber head push speed, hardness of the rubber head, the speed of the production equipment, printing effect and production control.